Dedicated Professional Team

One Stop Services

R&D Department

We’ve our own sample development facilities .

To ensure quick support and reduce sampling lead time we’ve well equipped sample room–including the dummy to develop maximum types of samples.

The new design and innovation are the heart of the fashion industry.

Design studios where we’ve done potential investment to create new design, style and set fashion trends. Two times in every year (Spring – Summer and Autumn – Winter) we offer our collection to customers to choose their desired style which significantly reduces R&D lead time of our buyers. Also, they can customize the style and fabrication with ornaments.

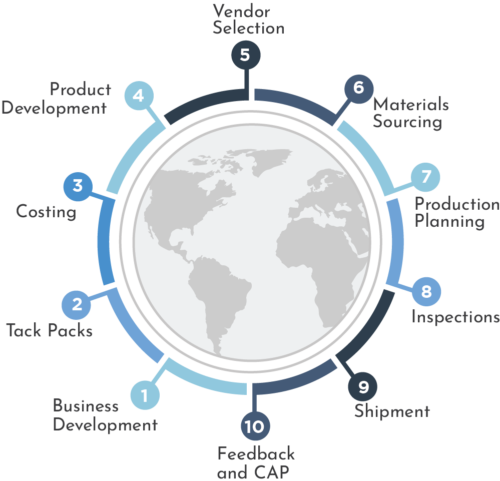

Integration, efficiency, and productivity in one place.

Our digitalized CAD room is giving extra mileage to our customers about maximum use of fabrics, creating automated data sheets and pre-costing, pattern digitalization, grading and marker services.

In-house testing facility.

Primary testing facility to check some essential parameters like appearance test, color fastness to light, color fastness to water, pH, GSM, rubbing, twisting and washing.

Huge Enlisted Vendors

We produce our products in compliant factory.

Our main strength is our onboarded factories providing quick supports to our buyers. We follow a standard procedure in factory onboarding. Before onboarding any supplier we operate 4 individual audits like financial audit, compliance audit, quality audit and management audit as our buyers feel comfort about shipment and quality.

World Prestigious LEED Certified Factory in Bangladesh

We Work All Ranges of Factory

Huge Range of Products

Our separate teams handle knit, woven, sweater and denim (both for men and women) with tops and bottom ranges.

STL separated its team based on product categories, and each team contains individual merchandisers, quality controllers, and commercial people.

Products Presentation

We manufacture high quality products according to different casts, culture, and seasons.

STL develops a number of fabrics, trims, and styles based on seasons like Spring – Summer (SS), Autumn – Winter (AW) and makes presentations for potential customers.